New HIDS Drum Scales!

Click Here to Learn More!Intrinsic safety (IS) is a protection technique for the safe operation of electrical equipment in hazardous areas by limiting electrical and thermal energy, available for ignition to safe levels.

Download the Free Guide:

Safe, Easy Solutions for Weighing in Hazardous Areas

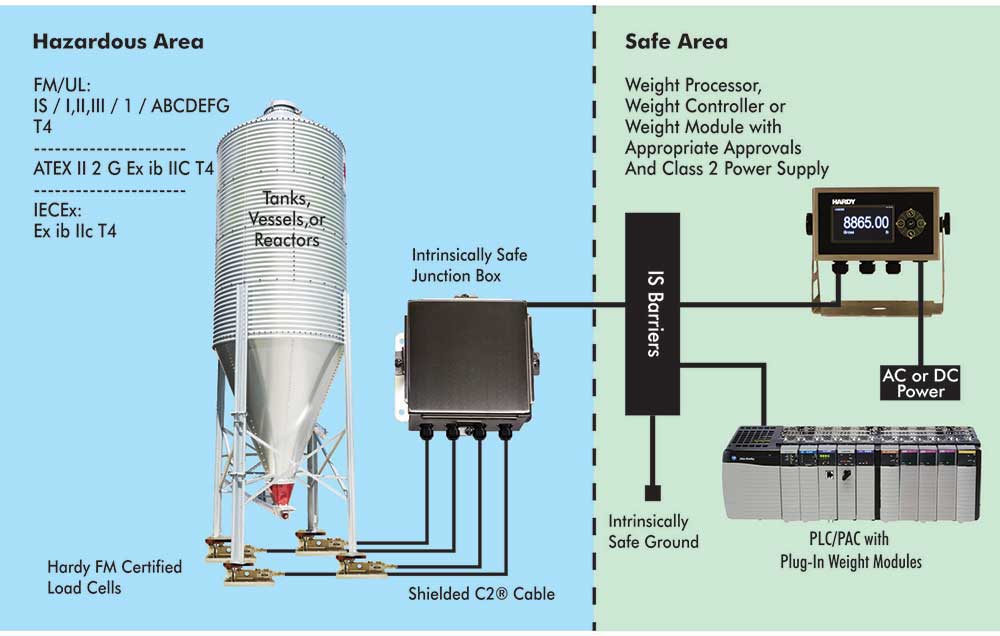

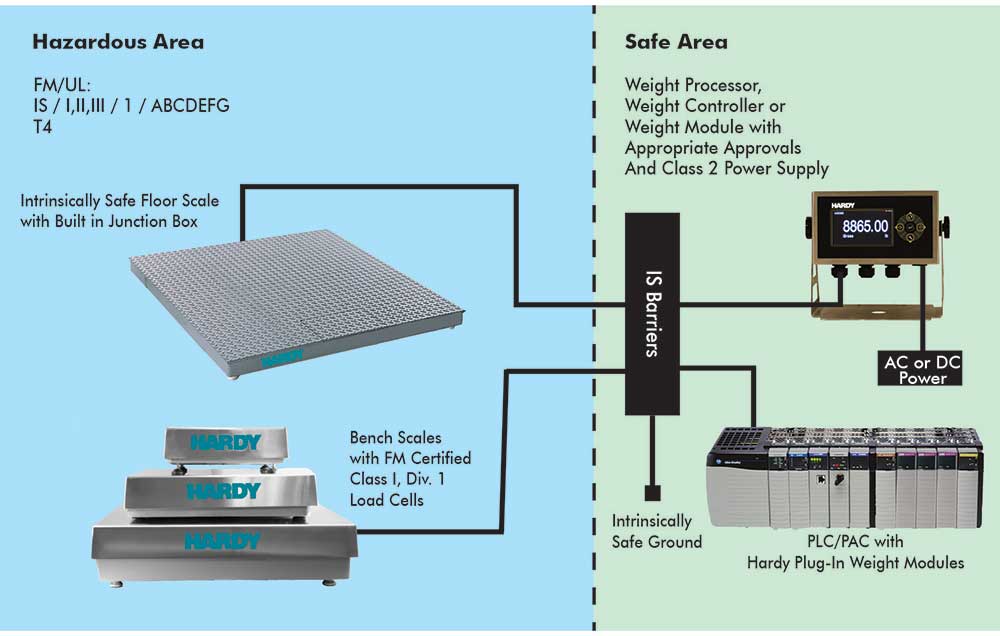

For potentially hazardous Class I, Div. 1 environments, Hardy Process Solutions has designed safety into its components with an appropriate level of protection for different applications. Hardy recommends using intrinsically safe low-energy components in hazardous areas (including load cells, scales, and summing boxes) and limiting power and current to them through intrinsic barriers that prevent energy from crossing over from the safe area.

For Tanks, Vessels, Mixers or Reactors, a Typical Weighing System Configuration for a Hazardous Area: Use Intrinsically Safe Barriers to prevent energy and current from instruments in the safe area from crossing over to low energy equipment in the hazardous area.

Hardy Weight Processors and Weight & Rate Controllers use proprietary technologies that have great value for Hazardous Area applications and confined spaces. Our C2® Electronic Calibration allows calibration of the weighing system without ever entering the environment. Conversely, Integrated Technician® is used for system diagnostics and troubleshooting from the safety of the safe area thereby reducing risk to operators. Other features such as WAVERSAVER® are used to eliminate the effects of vibration on the weight signal so only Stable Weight is communicated to the Control System.

Hardy’s single-slot Rockwell® PLC/PAC modules read and condition data from strain gauge load cells and communicate it over the I/O chassis backplane to the processor. They provide basic weight data or are loaded with sophisticated algorithms to perform application-specific industrial weighing processes from simple batch weighing to loss-in-weight control, filling, or dispensing. Modules are available for Allen-Bradley® ControlLogix®, CompactLogix®, Micro800®, or POINT I/O chassis.

Floor & Bench Scale Weighing System Configuration For a Hazardous Area: Use Intrinsically Safe Floor or Bench Scales with built in summing cards and IS Barriers to prevent energy from instruments in the safe area from crossing over to low energy IS scales in the hazardous area.

Hazardous (classified) locations might exist in any manufacturing location with vapors, dust or flyings, but are common in large bakeries (flour), plastics manufacturing plants (vapors or dust), chemical plants (vapors), paint-finishing locations (vapors), and grain silos (dust or flyings), to name just a few. Other examples include locations where vehicles are fueled or any transfer mechanisms for inherently hazardous materials.

Learn More About the Definitions of Hazardous AreasIntrinsic safety (IS) is a protection technique for safe operation of electrical equipment in hazardous areas by limiting the energy, both electrical and thermal, available for ignition.

Learn How to Reduce Risk in Hazardous Areas With Intrinsically Safe Weighing SolutionsIn North America, the most widely used hazardous location classification system is defined by the National Fire Protection Association (NFPA) Publication 70, National Electric Code® (NEC) in Articles 500 to 506. These regulations specify the type of hazardous substances that are or may be present in the air in quantities sufficient to produce explosive or ignitable mixtures.

Learn More About the Regulatory Agencies for Weighing in Hazardous AreasIntrinsic Safety Barriers are essential components of an intrinsically safe application. These devices limit current, voltage, & total energy delivered to a sensor or summing card located in a hazardous area. When used in areas with hazardous chemicals, gases or other ignitable atmospheres, limiting the energy helps prevent any possible fires & explosions.

Learn More About Intrinsic Safety Barriers Compatible With Hardy Weighing Systems