New HIDS Drum Scales!

Click Here to Learn More!Precision weighing systems from Hardy are designed specifically to work in batching and blending applications to ensure that your process has the same result every single time. There are two types:

Sequential batch control is a "gain-of-weight" application where multiple ingredients are added one at a time into a single weigh hopper mounted on or suspended by one or more load points (load cells and mounting hardware). Hardy's controllers work with a PLC, PAC, DCS, or PC to open and close the dispensing gates or valves while weighing the addition of the ingredients. They also open and close the discharge gate or valve of the weigh vessel for total or incremental discharge of the batch contents.

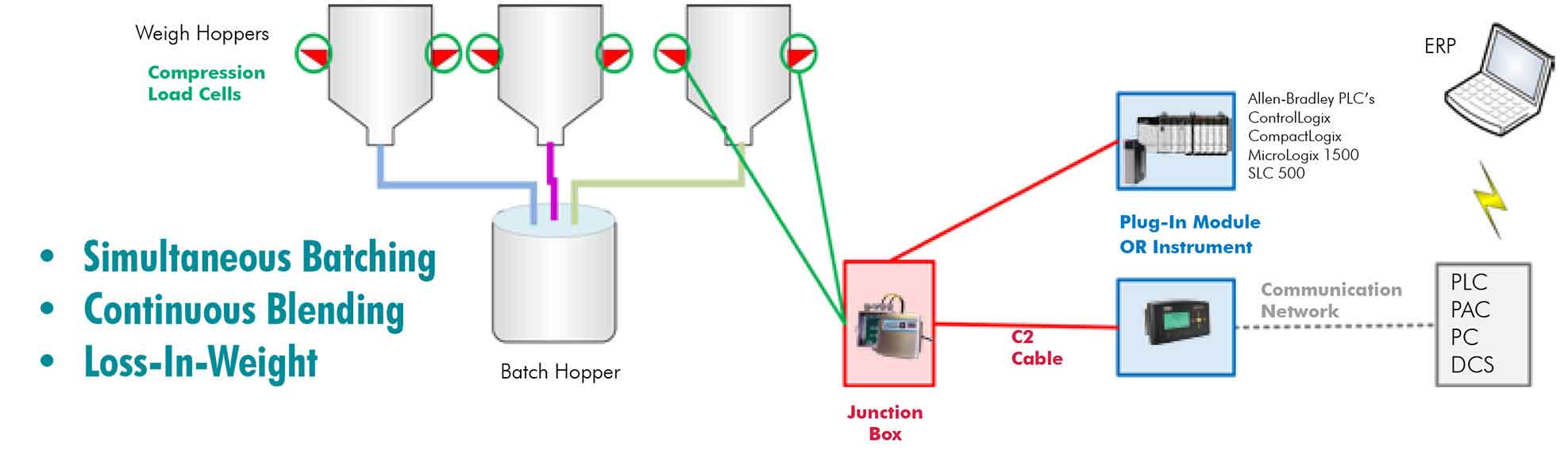

Simultaneous batch control is a "loss-of-weight" application where multiple ingredients are added to a single vessel at the same time. Hardy controllers dispense ingredients from weigh hoppers and/or feeders. They open and close the dispensing gates or valves of weigh hoppers that are mounted on, or suspended by, one or more load points (load cells and mounting hardware); control the rate of flow of material through feeders on scales; open and close the discharge gate or valve of the batch vessel for total discharge of the contents.

The initial cost of setting up a simultaneous batch system is more than a sequential batch system, but the batch/blend process is faster. Faster batching and blending means more product made in less time.

We provide solutions that range from weight to full rate control. They can be stand-alone systems or connected to host computers or programmable logic controllers (PLCs). The system should run in automatic, semi-automatic, manual, or a combination of all three modes, operating gates, valves, feeders, and pumps as well as downstream mixers and metered liquids. Hardy controllers automatically tare the net weight and sequence to the next ingredient to be batched.

Some ingredient amounts are so small that they can't be accurately weighed in the same hopper as a major ingredient. A batch system with Hardy's instrumentation can pre-weigh these minor ingredients and then automatically feed the material into the main batch hopper or have the PLC hold the batch process to allow for material to be added in by hand. The number of formulas/recipes is endless, limited only to the available memory.

Key Hardy Process Toolbox core technologies are designed to support critical batching and blending processes.

WAVERSAVER®ignores Vibrations made by equipment like conveyors, augers, and mixers in batching operations, which can cause plant and process vibration. Hardy’s WAVERSAVER technology provides quick and accurate weight reading by ignoring unwanted vibration. That means that a mixer's ingredients can be weighed while it's running.

Hardy’s C2® electronic calibration eliminates costly calibration fees associated with batching systems. C2 allows YOU to calibrate without tons of test weights, and even with the material in your vessel. This system reduces downtime for installation or repairs and greatly reduces test weight-related injuries. In addition, it ends your material substitution headaches.

Secure Memory Module (SMM) automatically stores and protects your critical setup and operating parameters and can transfer this information to a PC for backup or to another controller restoring all your critical processes, making your batching system operational again within minutes.

To learn more, visit our Case Studies on batching and blending.