Legacy Product: HI LPD Load Point Assembly for Reference Only

Obsoleted. Migration path is HIDSB series

Hardy Process Solutions has legacy load point assemblies that may have been upgraded to newer versions. This information is for the HI LPDC Series Load Point Assemblies and is provided to support customers who may have purchased this product in the past.

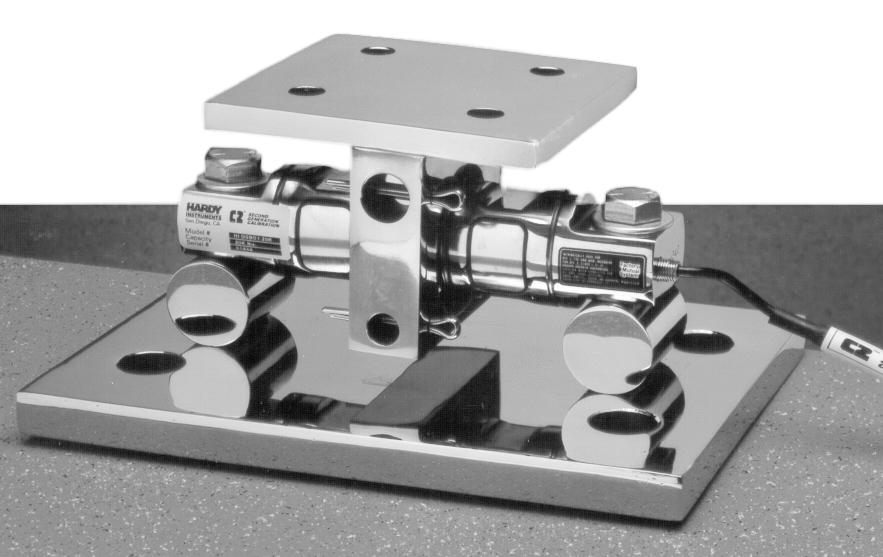

The Hardy HI LPD Series Load Point Assembly is designed to provide accurate output in the most demanding applications. The load point assembly consists of heavy-duty mounting hardware and a load sensor.

The HI LPD load point assembly is a self-centering, center-loaded, double-ended shear beam rigidly supported at both ends. The shear beam is sealed with a waterproofing compound and supplied with a minimum of thirty (30) feet of cable. The HI LPD is designed to resist angular effects and reduce moment sensitivity. The load point assembly comes standard with C2® Second Generation Calibration.

This feature allows the load point, to be electronically calibrated without the use of test weights. The mounting hardware uses a sliding pin design that reduces the possibility of error-producing side loads and compensates for thermally induced expansion and contraction of the scale and associated support structure. The need for conventional check rods when used for static loads is virtually eliminated. The HI LPDC Series mounting hardware is available either in stainless steel or mild steel, covered with chip-resistant dual epoxy paint.

Excitation (VDC)

- 10 Nom., Max. 15

Rated Output (mV/V)

- 3 ± .003

Zero Balance (Max.)

- 1% of Full Scale

Combined Error

- 0.03% of Full Scale

Non-Repeatability

- 0.01% of Full Scale (.02% for Stainless Steel)

Creep (Max.)

- 0.03% of Load in 20 Minutes

Temperature Sensitivity (Max.) Output

- 0008% of load /°F or .00018%/°C (.002% for Stainless Steel)

Zero

- 0015% of Full Scale/°F or .005%/°C

Resistance

- EXC: 700 ohms ± 3.5

- SIG: 350 ohms ± 3.5

Operating Temperature

- -65°F to +200°F or -54°C to +93°C

Compensated Temperature

- 0°F to 150°F or -18°C to +65 °C

Safe Overload

- 150% of Full Scale

Safe Side Load

- 100% of Full Scale