Now Includes Hazardous Area Certifications

Hardy now has a new line of lift-deck wash down scales designed to meet the needs of the most demanding applications, including use in hazardous areas.

These process weighing scales combine best-in-class durability with Hardy’s Process Toolbox features: weightless calibration (C2®) and operator diagnostics (INTEGRATED TECHNICIAN®). Hardy Lift Deck Floor Scales offer manufacturers multiple ways to reduce their maintenance costs and downtime.

DESIGNED FOR ANY ENVIRONMENT

Hardy Lift Deck Floor Scales are designed and built for hazardous areas, such as those with chemicals and heavy washdown industrial environments, yet are easy to use and install with the latest advancements in weighing technology. Just level the deck, attach the included twenty-foot cable, calibrate (if a C2® compatible instrument, set your reference), verify and begin weighing.

Hardy Lift Deck Scales are available in three sizes from 36 x 36 inch to 60 x 60 inch in 1, 2, and 5 thousand pound capacities. Hardy Lift Deck floor scales have two to four handles on the decks for easy lifting to facilitate installation and cleaning in pit frames.

C2® ELECTRONIC CALIBRATION

With a Hardy weight controller, C2® load sensors enable fast, accurate, electronic calibration without test weights at just a push of a button The easy-to-use C2® system reduces downtime for installation and repairs and eliminates test weight related safety risks.

INTEGRATED TECHNICIAN®

Each scale has built-in INTEGRATED TECHNICIAN® (IT) circuitry. When coupled with a Hardy controller, the scale provides diagnostic and troubleshooting tools that read individual weights and voltages to aid you in isolating problems. Together, Hardy C2® and IT eliminate the need to open the junction box, reducing the risk of moisture ingress. The junction box remains sealed reducing the risk of contamination for heavy wash down applications.

HERMETICALLY SEALED LOAD SENSORS

The heart of any scale is the load sensors. All Hardy Lift Deck floor scales come standard with four matched Hardy ADVANTAGE® IP69K stainless steel, true hermetically-sealed sensors — sealed at both the gauging area and cable entry for long life. All are matched and calibrated for mV/V and mV/V/ohm. This eliminates the need for corner adjustment and potentiometers in the junction box, allowing a sensor to be replaced without calibration. Hardy ADVANTAGE® sensors use a blind hole technique ensuring the load is applied at a precise location to provide an accurate reading, weighment after weighment.

RUGGED, LOW PROFILE DESIGN

Rated for 250,000+ load cycles under normal loading conditions,* these lift deck floor scales are built to last. With a deck height of only 4.2 inches and 100% end loading, Hardy Lift Deck Floor Scales feature a hydraulic system that enables one person to easily lift the deck for cleaning. Durable rubber-based feet are height adjustable from below the platform for easy leveling.

HAZARDOUS AREA CERTIFICATIONS

The integrated summing box is sealed and has approval for use in the following hazardous areas:

- Class I, Division 1, Groups A, B, C, D, T4; Zone 0, Group IIC, T4; Division 2, Groups A, B, C, D, T5

- Class II, Division 1, Groups E, F, G, T4; Zone 20, Group IIIC; Division 2, Groups F, G, T5

- Class III, Division 1, T4; Division 2, T5

Call us today at 800-821-5831 or 858-278-2900 to buy a new lift deck scale. Or email us at hardyinfo@hardysolutions.com.

Platform

- 0.25 inch thick smooth or safety tread deck

Height

- 4.2-4.4 inches (10.6 -11.2 cm) adjustable 0.2” or 5 mm

Accuracy

- Combined Error: 0.02%

- Repeatability: 0.01%

Overload Capacity

- 100% of rated scale capacity

End Loading

- 100% of rated scale capacity

Cable Length

- Platform to Instrument - 20 feet (for longer cable lengths, contact the Factory)

Construction

- Stainless Steel - Type 304

Duty Cycle

- +250,000 load cycles under normal loading conditions*

Load Sensor

- IP69K rating for washdown applications

- C2® or manual calibration

- stainless steel, hermetically sealed

- blind hole loading

HI 6011 Summing Box Power Rating

- 5 VDC, Class 2 source, max. 50 mA

- For Class I and II, Division 1 Hazardous (Classified) Locations, and Class 1, Zone 0 and 2 Groups IIC, Zone 20 and 22 Groups IIIC, power must be supplied to the summing box through approved intrinsically safe barriers per control drawing 0594-0010

Summing Box Specifications

- NEMA 4 Enclosure

- Hardy 6011 Summing Card with 4 integrated individual load sensor terminal blocks with cable glands

- INTEGRATED TECHNICIAN® circuitry

Certifications

- UL. CE, CUL

- RoHS3 and REACH Compliant

- Approved for use in Hazardous Area Locations for US & Canada

- Class I, Division 1, Groups A, B, C, D, T4; Zone 0, Group IIC, T4; Division 2, Groups A, B, C, D, T5

- Class II, Division 1, Groups E, F, G, T4; Zone 20, Group IIIC; Division 2, Groups F, G, T5

- Class III, Division 1, T4; Division 2, T5

Scale Excitation

- 5vdc +/-5%

Warranty

- Two Years

*Contact Hardy for further information

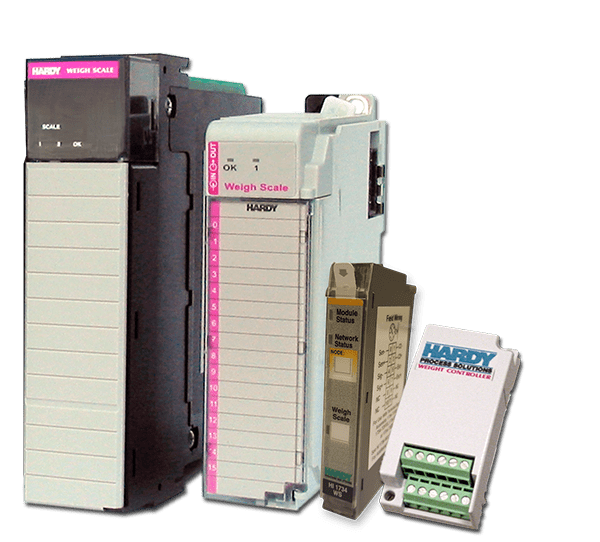

The Hardy Process Toolbox is a set of productivity tools that support industrial weighing functions. Each tool saves time, increases accuracy, improves efficiency, or reduces risk in process weighing applications, including WAVERSAVER® to eliminate vibration, C2® electronic calibration, and Integrated Technician® to name just a few.

The Hardy Lift Deck Floor Scales feature the following Toolbox technologies:

C2® Electronic Calibration

The Hardy C2® (or eCAL as it is known in China) core feature provides quick and easy electronic calibration of a weighing system without the need for heavy test weights. Unlike calibration with test weights, all the live weight on the scale does not have to be removed and heavy test weights do not have to be repeatedly put on and off the scale. As soon as your scale system is installed, it can be C2 or eCAL calibrated, and proper scale installation verified. The result is a calibration that is easier, quicker, safer, and typically more accurate.

INTEGRATED TECHNICIAN® Operator Diagnostics

Hardy's INTEGRATED TECHNICIAN (IT) core feature helps you troubleshoot your weighing system and diagnose problems from the front of the instrument or via the PLC. These tests display system weights, voltages, and pass/fail displays to help isolate a problem to the instrument, cabling, or sensors, helping to reduce maintenance costs.

Through the Hardy Weighing Instrument, the Hardy Floor Scales have access to the following additional technologies.

WAVERSAVER® Vibration Eliminator

Hardy's WAVERSAVER core technology eliminates the effects that surrounding vibration has on the scale weight signal, providing only true data for fast, accurate weight reading.

Embedded Web Server

Access your instrument from any computer browser, easing setup and making diagnostics fast and easy. Use the Embedded Web Server to set up all parameters from anywhere on the Ethernet network.

Secure Memory Module Stores Configuration Data

Hardy's Secure Memory Module (SMM) uses a standard SD card to automatically back up critical weighing system data, allowing you to transfer it to another like controller in a few minutes. You can also use the card to easily back up your controller data onto a PC.