-

-

Brauchen Sie Hilfe?Buchen Sie noch heute ein persönliches Beratungsgespräch mit einem Hardy-Wiegespezialisten!Kontaktieren Sie uns

-

-

Neue HIDS-Trommel-Skalen!

Klicken Sie hier, um mehr zu erfahren!How you can troubleshoot an unstable weight reading

There are many reasons why your weight readings could suddenly start drifting. Weight drifting over time can happen to any instrument, and it is usually not the instrument that is the cause. More often the scale input to your controller may be compromised. One of the most common reasons for drifting appears at times of the year when low humidity causes static buildup on your load cells and/or weight controller. As the humidity changes, so does the static charge in the air. Your weight controller is looking for very small changes in input voltage, and static discharges can cause the weight reading to drift.

The most effective way to determine what is causing your weighing system to drift is to isolate the problem to the load cell(s), the controller, Junction Box wiring, or the cables. The problem could also be caused by external mechanical binding.

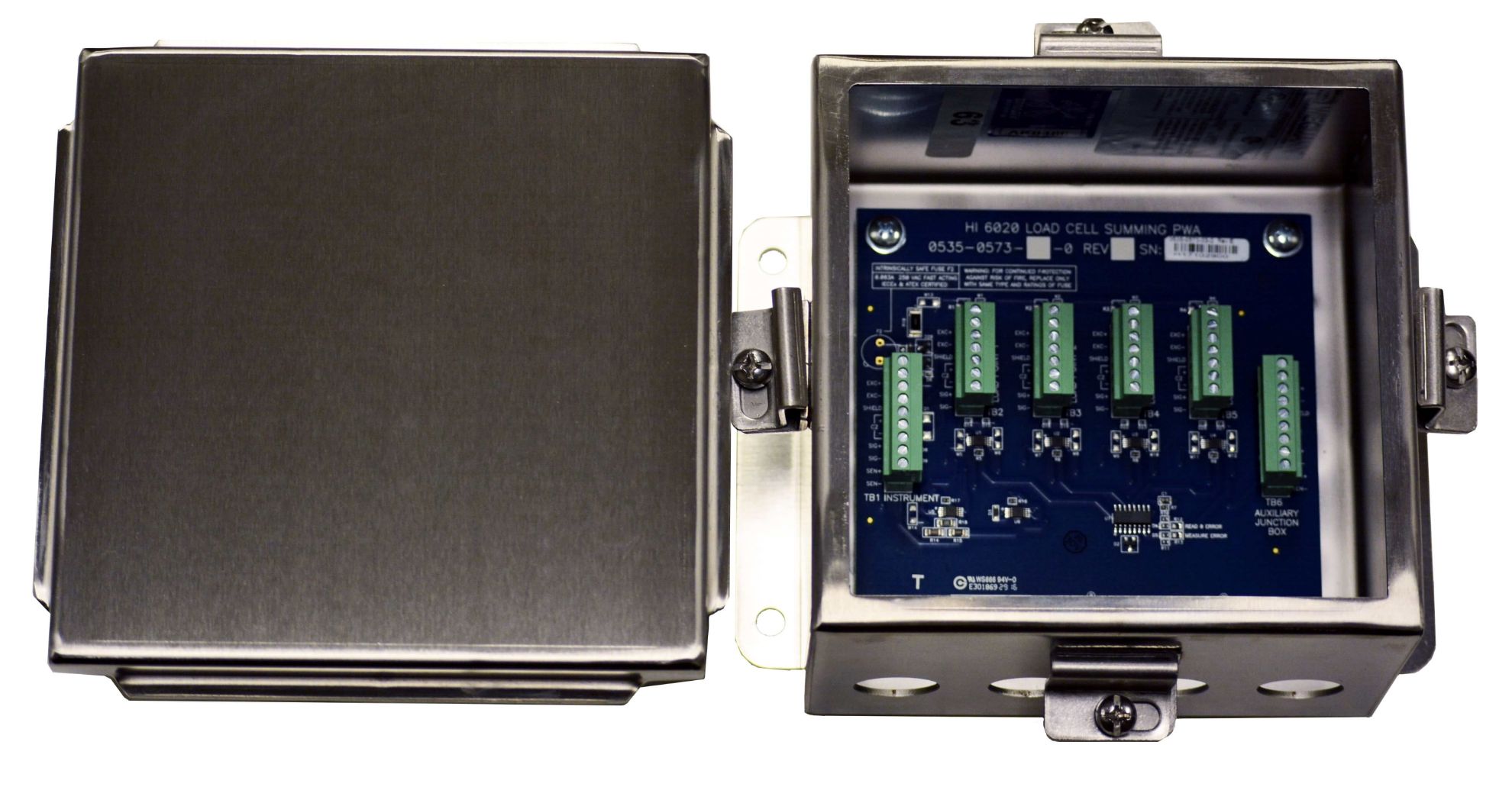

These tests are used to diagnose drifting or unstable weight reading problems. It requires a Hardy IT Junction Box for full utilization (for example, the HI 215IT or the HI 6010IT). The ability to read the weight seen by the individual load sensors allows you to use this test for making cornering, leveling, and load sharing adjustments to the weighing system.

INTEGRATED TECHNICIAN® (IT) provides the following problem detection support:

First, use the IT Stability Test to determine if the problem is in the instrument or the cable. Check all the load cell connections to make sure all connections are tight. Check in the Junction Box and double-check the connector on the back of the controller. You should also make sure there is no moisture trapped in the Junction Box. If water or moisture gets into the Junction Box, the load cell cable and/or load cell may have to be replaced due to the fact that cables can "wick up" the moisture and damage the load cell (and cause drifting symptoms). Next, use the IT Weight and Voltage Test and read the weight of each individual load cell in the system to see if that load cell might be causing the problem. Replace the bad load cell.

If this is inconclusive, you will need to perform a calibration with the scale empty and then record the mV/V levels from the load cell(s). You can find the mV/V levels by going into the IT Weight and Voltage Test section of your Hardy controller.

The following Hardy weight controllers have the INTEGRATED TECHNICIAN feature: HI 1746-WS, HI 1756-WS, HI 1756-2WS, HI 1769-WS, HI 1769-2WS, HI 1756-FC, HI 1769-FC, HI 1756-1DF and HI 1756-2DF (that use commands in the ladder logic). The HI 2151/30WC, HI 3030, HI 4060, HI 6300, HI 6310, and the HI 4050 use the front keypad and display to run the IT programs. To utilize the IT feature you will need an IT-capable controller (listed above) equipped with an IT-capable junction box (HI 215IT or HI 6010IT).

If your Hardy instrument does not have IT then you will need to get the mV readings using a volt meter at the back of the controller. Use the instructions below to measure the signal voltages and record the mV/V readings for reference.

The next test helps establish if a load cell's millivolt output has changed when you repeat the same weight levels, if the weight drifts at a high level. Record that weight and wait for the scale to drift. This duration can change with the cause. Heating and cooling is normally a 12-hour cycle. Shorter cycle times may help determine the source of your drift. Typically a load cell is stable to +/- 0.01mv across the signal output of a static scale. Loose gauges are detected with a millivolt meter across the individual load cells' signal outputs. Monitor the output and that should be stable to +/- 0.01mv. Apply a load to the load cell you are monitoring. The mV signal will rise proportionate to the force applied and when the force is removed, return to the original mV level as fast as the meter can respond. Any slow response can indicate the load cell or a mechanical bind.

Now operate your Hardy weight controller as you normally would, and when the weight drifts again empty the scale. Your reading may not go to zero, but it should put the scale in the same condition as when you took the reference reading. Now, go back into the INTEGRATED TECHNICIAN mode (or check the voltages with your meter) and check to see what the mV/V reading is again. If your mV readings are higher or lower, then your scale is sending a different value signal to your Hardy weight controller under the same circumstances. This would indicate there is a problem with your scale not being repeatable.

If the mV/V readings are the same, then you may have a problem with your controller. Contact Hardy Technical Support for assistance at no charge.

WAVERSAVER, C2, and INTEGRATED TECHNICIAN are registered trademarks of Hardy Process Solutions.