-

-

Brauchen Sie Hilfe?Buchen Sie noch heute ein persönliches Beratungsgespräch mit einem Hardy-Wiegespezialisten!Kontaktieren Sie uns

-

-

Neue HIDS-Trommel-Skalen!

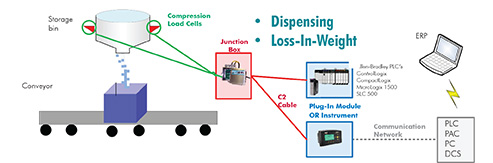

Klicken Sie hier, um mehr zu erfahren!Supply bins in loss-of-weight applications are suspended (Tension) or supported (Compression) by load points to weigh the dispensed material into receiving containers. Hardy controllers can open and close the discharge gate or control the rate of flow from a feeder, while precisely weighing the loss of material from the scale. Relays in a Hardy controller are designed to automatically refill the supply bin when a programmed weight is reached.

Download Part One: The 4 Sources of Filling and Dispensing Errors

Download Part Two: Solutions to Filling And Dispensing Errors

Hardy instruments that are used for dispensing include weight, and rate controllers. The Hardy HI 1756-nDF for ControlLogix®, the HI 3010 Filler/Dispenser, and the HI 4060 Rate controller all have the applications pre-programmed while other controllers supply stable accurate weight for programs that run in other devices. Hardy instrumentation works with standalone systems or connects to host computers, PLCs, PACs, or DCS. Track total net weight with Hardy's totalizer feature, which adds the total amount of net weight dispensed. High resolution and fast update rates allow for the precise cut-offs required for the dispensing process to ensure accuracy.

Dispensing into Intermediate Bulk Containers is also associated with Loss-of-weight systems. IBCs are suspended (Tension) or supported (Compression) by load points to weigh the dispensed material received into containers. IBCs are often exchanged in the middle of a dispense operation when they run out of material. A Hardy rate controller retains the original amount dispensed from the first IBC in memory so that it knows how much material is required from the second IBC to complete the desired weight in the receiving container. Without this feature, excess material would be lost from overfilling when switching.

Hardy’s solutions deliver accelerated returns on investment, by enhancing productivity and adding value across the supply chain. Hardy’s solutions are easy to install, configure, commission, and operate. They are safer to maintain and save you time, money, raw materials, and/or finished product. Visit our Case Studies today!