Material Feed Management by Weight for ControlLogix® PLCs

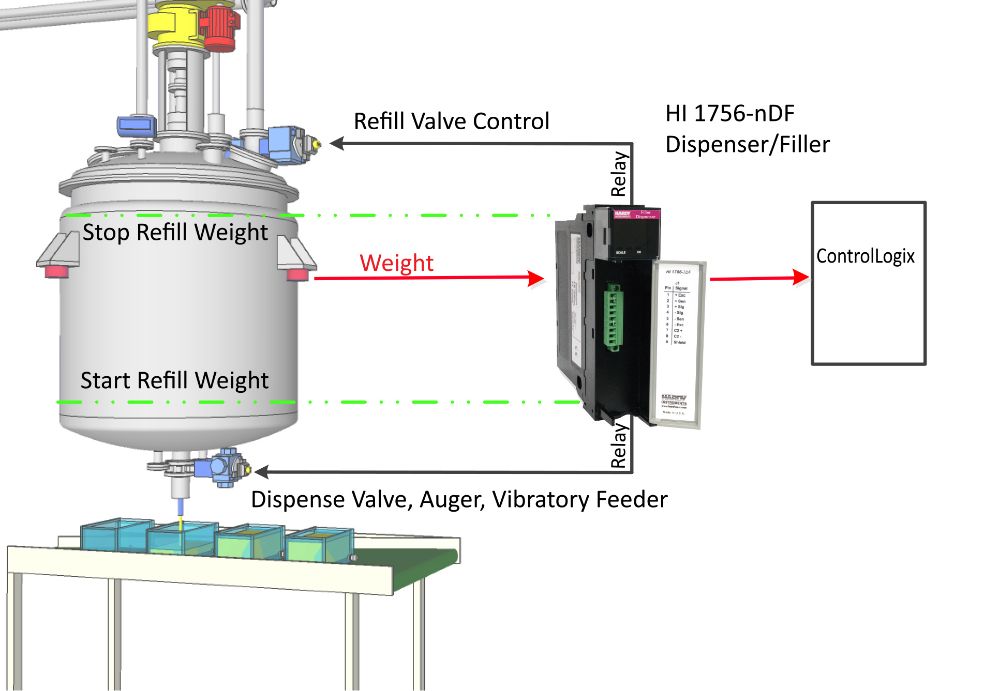

The HI 1756-nDF ControlLogix Dispenser/Filler module is the easy answer to a variety of material feed applications, especially, when speed and accuracy of the feed are paramount to the process. The module batches, fills, or dispenses aggregates, granulates, liquids, or gases, handling the entire feed process.

The internal set point control is moved closer to the process, by taking it out of the PLC and into the module. This eliminates timing issues created by non-deterministic messaging. To compensate for flow rate variations during the feed, real-time target (preact) adjustments can be sent from the PLC, or be calculated by the module. Modules come in single or dual-scale configurations. Each scale is fitted with a choice of two integrated solid state DC or AC relays to control fast and slow feed rates.

The HI 1756-nDF will calculate and transmit gross weight, net weight & flow rate outputs simultaneously. Non-linear flows due to varying densities and head pressures are a thing of the past with its predictive algorithm automatically adjusting the system’s setpoint preact function.

These modules can be inserted and removed under power without disruption of any other modules in the system (racks). This makes it possible to replace a failed module while keeping the rest of the system running. Status indicators are provided on the front of the module for fault status. A status block will provide information to the processor for alarming and troubleshooting.

Visit our Case Studies or Application Notes for more information on material feed management.

Rockwell Add-On-Profile (AOP)

Hardy Process Solutions has the highest level of integration with Rockwell Automation® PLCs, with backplane integration and Add-on-Profiles (AOPs). These integration tools are designed to provide an EASY and seamless setup with Rockwell PLCs and PACs, using RSLogix® or Studio 5000®

Update Rate

- 100 updates per second (10 ms)

Resolution

- Internal, 1:8,388,608

Input

- Up to eight 350-ohm Full Wheatstone Bridge, Strain Gauge Load Sensor/Cells (5-volt excitation) on one vessel

Non-Linearity

- 0.0015% of Full Scale

Common Mode Rejection

- 110dB at or below 60 Hz

Common-Mode Voltage Range

- 2.5VDC maximum (with respect to earth ground)

Backplane Input Voltage

- 5 VDC and 24 VDC

Backplane Current Load

- <1 Amp at 5 VDC

- 0.0125 Amps at 24 VDC (with 4-350 Ohm Load Cells)

Backplane Power Load

- < 5W at 5 VDC

- < .3W at 24 VDC with 4-350 Ohm Load Cells

C2® Calibration Signals

- Isolation from digital section 1000 VDC minimum

Cable Lengths

- 1000 feet maximum of C2 authorized cable

- 250 feet maximum of C2 authorized cable (Maximum of 4 load sensors) with IT Junction box

C2® Maximum Cable Length

- 1000’ for C2, Non-C2, or Summing Card

- 250’ for IT

Load Cell Excitation

- 5 VDC +/- 1.15 W maximum

- Isolation from digital section 1000 VDC minimum

Number of Weigh Scale Channels

- HI 1756-1DF 1 Weigh Scale Channel

- HI 1756-2DF 2 Weigh Scale Channels

Averages

- 1-255 User-selectable in Single Increments

- Averages current and previous N samples to provide the current weight value

WAVERSAVER® Vibration Immunity

- User Selectable

Outputs

- Two solid state DC or AC relays per weigh scale channel - For resistive loads only (Form A - Normally Open)

DC Relay

- 5 to 30 VDC

- 0ºC to 25ºC: max current = 3A

- 0ºC to 40ºC: max current = 2A

- 0ºC to 60ºC: max current = 1A

Minimum load

- 2mA current

Operating Temperature Range

- 0 to 60º C (32º F to 140º F)

Storage Temperature Range

- -40 to 85º C (-40 to 185º F)

Certifications

- UL

- CE

- RoHS 3 and REACH

Warranty

- Two-year warranty against defects in workmanship

All specifications are subject to change without notice. Please contact the Hardy factory or visit our website for the latest specifications.

The Hardy Process Toolbox is a set of productivity tools that support industrial weighing functions. Each tool saves time, increases accuracy, improves efficiency, or reduces risk in process weighing applications, including WAVERSAVER® to eliminate vibration, C2® electronic calibration, and Integrated Technician® to name just a few.

The HI 1756-nDF features the following Toolbox technologies:

WAVERSAVER® Vibration Eliminator

Hardy's WAVERSAVER core technology eliminates the effects that surrounding vibration has on the scale weight signal, providing only true data for fast, accurate weight reading.

C2® (or eCAL) Electronic Calibration

The Hardy C2® (or eCAL as it is known in China) core feature provides quick and easy electronic calibration of a weighing system without the need for heavy test weights.

INTEGRATED TECHNICIAN® Operator Diagnostics

Hardy's INTEGRATED TECHNICIAN (IT) core feature helps you troubleshoot your weighing system and diagnose problems from the front of the instrument or via the PLC. These tests display system weights, voltages, and pass/fail displays to help isolate a problem to the instrument, cabling, or sensors, helping to reduce maintenance costs.

FEED-MASTER

FEED-MASTER is a set of software controls designed to control volumetric and gravimetric feeders.